Pedal Operated Washing Machine free of cost

ABSTRACT

In the current world, washing laundry

is a difficult, time-consuming task that falls solely on human being. People

spend around 8.5 hours each week scrubbing each piece of their family’s

clothing and wringing out the harsh washing solution by hand. As electricity charges

are increasing day by day and the need for electricity increases. As, powered

washing machines exist, but they are impractical in rural regions because

running water and electric are expensive or unavailable. Many inventors already

tried to build machines for these regions but they have been failed. Their machines

were either expensive to build because they require imported parts or they do

not wash properly. Compared to other housing staff washing machine is a popular

electronic home appliance, which is found in almost every household. In this

current era, a washing machine is highly popular because of its great use. It

does the laundry so fast, saving a lot of time and labour. It can manage to do

so, quite effectively and efficiently, as it follows a set washing process. Our

desired invention will be low cost, pedal-powered washing machine (without

electricity) that is designed around readily available parts. Its innovation is

its simplex design and its use of inexpensive plastic barrels and bicycle

components. The pedal based machine is reliable, easy to operate and uses no

electricity.

INTRODUCTION

Definition

1.1.1

Washing

:

Washing is one of necessary and important

household work among rest of other works.

Washing is an act of

applying water or some other liquid to (something or someone) for the purpose

of cleansing; cleanse by dipping, rubbing, or scrubbing in water or some other

liquid.

1.1.2

Rinsing :

Rinsing is act of

removing soap from (clothes, etc.) by applying clean water in the final stage

in washing.

1.1.3

Washing Machine :

Generally we can describe A washing machine which

washes clothes. It is known as laundry machine also, clothes washer, or washer,

a machine used to wash laundry, such as clothing and bed sheets other cotton cloths. Washing Machine is

mostly applied to home and that machines that use water as opposed the dry

cleaning (which can be used alternative cleaning fluids, and is performed by

specialist businesses) or ultrasonic cleaners.

1.1.4

Pedalling :

Pedalling is a foot-operated lever used

for actuating or to control a mechanism, as in a loom, sewing

machine etc.

1.2

History of washing :

Hand or feet washing machines were not used in ancient time.

The first washing machine was designed by H.Sidgier of Great Britain in 1782.

It was consist of a cage with wooden rods and a handle for turning. From this

design in the late 1800 century different companies started producing hand

operated machines that used paddles. James King in 1851 brought the revolving

drum. Hamilton Smith (scientist) in 1858

followed the revolving drum with the reversing action. The earliest manual

washing machines lessened the motion of the human hand on the washboard

(pressing and rinsing), by using a lever to move one curved surface over

another and rubbing clothes between two ribbed surfaces. This type of washer

was first patented in the USA in 1846 and survived as late as 1927 in the

Montgomery Ward catalogue. In 19th century, America introduced the first

electric clothing washers (washing machine), in which a motor rotated the tub. That

time motor was not too much popular and water often dripped into it causing

short-circuits and jerking shocks. By early 1911, it was possible for the

general people to buy oscillating, cylinders, domestic washing machines with

sheet metal tubs mounted on angle-iron frames with perforated metal or wooden

slat cylinders inside. Beatty Brothers of Fergus, from Canadian Ontario was the

first company to produce an portable agitator washing machine. The early Beatty

machines had used ribbed copper tubs which were made from nickel or

nickel-chromium plated. Maytag technology was

the first firm to adopt agitator

technology in US. The vertical orientation of these machines became the

industry standard replacing the horizontal rotating axis of earlier machines. Around

the early 1940’s, enamelled steel was used and sold as being more sanitary,

easier to clean and longer lasting than the other finishes. The sheet-metal

skirt was also designed to extend below the level of the motor mount. In the

early 1920’s, a number of Canadian machines were offered with built-in gas or

electric water heaters. By the 1930’s, domestic water heaters were popular and

started to use in many homes and the washing machine heater was of little use

or no use. Later, the addition of a motor-driven drain pump at this time moved

the machine one step closer to complete accuracy washing and precising. After

that the next development of the washing machine was the fitting of a clock

timing device which allowed the machine to be set to operate for a

pre-determined length of wash cycle. Now, the operator no longer needed to

constantly monitor its action. By the early 1950’s, a lot of USA manufacturers

were started to supplying machines with a spin-dry feature to replace the

wringer which removed buttons, and caused accidents involving hair and hands

and severe injuring to the workers and the general people. In 1957’s, GERMANY, introduced

a washing machine equipped with five push buttons to control washing water

quantity, load, temperature, cloth amount, rinse temperature, agitation speed

and spin speed of the washer.

1.3

Purpose & Objectives :

Instead of doing household (washing cloths) work smartly

and easily washing machine have been implemented. The main objective of the

washing machine is to clean the dirty cloths using electrical power instead of

using human power. The washing machine is one of the major part of our daily

.As we are getting busy day by day as a result we are getting less time do our

daily household work.

1.4

Working Principle :

We will have

design the pedal powered washing machine which is simple mechanism for washing

cloth with the help of pedalling operation. It has one more advantage, the pedalling

operation just acts like an exercise to the human being .When pedalling system

starts to rotate it will rotate the washing blades by using the chain or belt arrangements.

The shaft is welded with the pinion which is fixed on the cylinder. The chain

or belt arrangement will gives the forward and reverse direction rotation for

the operation of washing cloth.

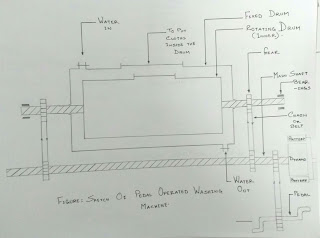

Fig: Sketch of Pedal Operated Washing Machine.

DESIGN OF PEDAL OPERATED WASHING MACHINE

3.1 Components

The

components used in the project are:

1.

Spur Gear

2.

Shafts

3.

Rotors

4.

Drum

5.

Pedal

6.

Chain

7.

Dynamometer

8.

Battery

9.

Hacksaw Blade

10.

Sprocket

11.

Others

3.1.1

Spur

Gears:

Among all of

the gears Spur gears (straight gears) are the most common type of gears. They are

having straight teeth, and are mounted on parallel shafts. Sometimes, many spur

gears are used at simultaneously to create very large gear reductions.

Spur gears are used in many devices that you can see all over

How Stuff Works, like the electric screw driver, dancing mosnter, pscillating

sprinkler, windup alarm clock, washing machine, cloth drier etc. But you will

not be able to find many in your car.

This is because the spur gear can be really loud. Each time a

gear tooth engages a tooth on the other gear, the teeth collides, and this

impact makes a huge sound. It also increases the stress on the gear teeth.

3.1.2 Shaft:

A shaft can be said as a rotating

machine element which is usually circular in cross section, which is used to

transmit power from one part to another, or from a machine which produces power

to a machine which absorbs power.

The

maximum permissible (design) stresses in bending (tension or compression) may

be taken as:

1. 112 N/mm2 for shafts with allowance for

keyways.

2. 84 N/mm2 for shafts without allowance for

keyways.

The

maximum permissible (design) shear stresses may be taken as:

3. 56 N/mm2 for shafts with allowance for

keyways.

4. 42 N/mm2 for shafts without allowance for

keyways.

The

material used for ordinary shafts is mild steel. When high strength is

required, an alloy steel such as nickel, nickel-chromium or chromium-vanadium

steel is used.

Most

Shafts are generally formed by hot rolling and finished to size by cold drawing

or turning and grinding.

3.1.3 Rotors:

The rotor is the main spinning

element of the rotor-spinning machine. Yarn quality, character working

performance of yarn productivity, & costs etc. all depend chiefly on the

total draft in rotor spinning is, therefore a combination of true draft from

the feed roll to the rotor (in the order of thousands) and a condensation to

accumulate the fiber groups into a fiber ring inside the rotor. The total draft

ratio is the ratio between the delivery or the take-up speed and the feed roll

speed. It is mandatory that approximately amount to the ratio should maintain

between the number of fibers in the sliver cross-section and the number of

fibers in the yarn cross-section.

3.1.4 Drum:

The drum is

the spinning section of the machine where you load your clothes into.

3.1.5

Pedal:

A bicycle

pedal is the part of a bicycle that helps the rider pushes with their feet to

start the propelling actions of the bicycle. It provides a connection between

the cyclist's feet or shoes. Initially the Pedals were attached to cranks

connecting directly to the driven (usually front) wheel. The safety bicycle, as

it is known today’s mordenized bicycle, came into being when the pedals were

attached to a crank driving a sprocket that transmitted power to the driven

wheel by means of a roller chain.

3.1.6 Chain:

Chain drive is a way of

transmitting mechanical power from one place to another. It is often used to

convey power to the wheels of a vehicle both in the two wheeler or four

wheelers, particularly bicycles and motorcycles means two wheelers. It has also

vast use in a wide variety of machines besides vehicles. Sometimes the power can be outputted by

simply rotating the chain, which can be used to lift or drag objects. In other

situations, a second gear might be placed and the power is recovered by

attaching shafts or hubs to this gear very smoothly. Though drive chains are

often simple and has oval loops, they can also go around corners by placing

more than two gears along the chain; gears that do not put power into the

system or transmit it out are generally known as idler-wheels. With the

variation of the diameter of the input and output gears with respect to each

other, the gear ratio can be altered. An example, when the bicycle pedal’s gear

rotate once, it causes the gear that drives the wheels to rotate more than one

revolution.

3.1.7

Dynamometer:

A dynamometer or "dyno", is a test

instrument used to measure torque and speed, which is used to calculate power

of a device such as an engine, electric motor, pump, transmission, or

generator/alternator. Dynamometers can be either motoring, in which a dynamometer

has a motor that can drive the device under test, and/or absorbing where the

torque and speed is determined by the power produced.

A

dynamometer’s other use is to determine the torque and power required to

operate a driven machine such as a pump. In that case, a motoring or driving

dynamometer is used. A dynamometer that is designed to be driven is called an

absorption or passive dynamometer. Dynamometer with dual mode like drive or

absorb is called a universal or active dynamometer.

3.1.8 Battery:

The Batteries we use are made of

electrochemical cell (or enclosed and protected material) that can be charged

electrically to provide a static potential for power or released electrical

charge when needed.

A battery generally consists of an anode, a cathode, and an

electrolyte.

The Common types of commercial batteries and some of their

characteristics and advantages. Battery types not shown include the Zinc-Air,

Flooded Lead Acid, and Alkaline batteries. However, limitations of batteries

are: these electrochemical processes are not continuous rather change the

chemicals in anode and cathode to make them stop supplying electrons. So there

is a limited amount of power available in a battery.

3.1.9

Hacksaw Blade:

A hacksaw is a

fine-toothed saw, originally and principally made for cutting metals, wooden

thins or others. They can also cut various other materials, such as plastic and

wood; an example, plumbers and electricians often cut plastic pipe and plastic

conduit with them. There are hand saw versions and powered versions (called power

hacksaws).

Blades

are available in standardized lengths, 10 or 12 inches (254 or 305 mm) for a

standard hand operated hacksaw. Medium hacksaws are 6 inches (152 mm) long.

Powered hacksaws can use large blades in a range of sizes, or small machines

may use the same hand operated blades.

3.1.10 Sprocket:

A sprocket (partially named

a sprocket-wheel) is a profiled wheel with many teeth, cogs or even sprockets

that mesh with a chain, track or other perforated or indented material. The

name 'sprocket' applies generally to any wheel upon which radial projections

engage a chain passing over it. It may be distinguished from a gear in that

sprockets are never meshed together directly, and differs from a pulley in that

sprockets have teeth and pulleys are smoothly workable

There

are four main types of sprockets;

Type 1: Plain Plate sprockets,

Type 2: Hub on one side,

Type 3: Hub on both sides,

Type 4: Detachable hub.

Sprockets should be as large as possible for

the given the application. Larger sprocket means the less the working load for

a given amount of transmitted power, allowing the use of a smaller-pitch chain.

However, chain speeds must be kept under 1200 feet per minute.

3.1.11 Others:

Others component used in the Pedal Operated

Washing Machine are:

Nuts/Bolts for tightening the contact.

Lubricants

used for getting a frictionless (almost) power transmission.

3.2 BILL OF MATERIAL

Name of the

parts

|

Number of

parts required

|

Material used

for parts

|

Outer Drum

|

1

|

Steel

|

Inner drum

|

1

|

Steel

|

Shaft

|

3

|

Iron

|

Gear

|

6

|

Alloy

|

Chain

|

3

|

Iron

|

Pedal

|

1

|

Iron

|

Battery

|

1

|

Default

|

Hacksaw Blade

|

1

|

Steel

|

Dynamometer

|

1

|

Default

|

Bearing

|

5

|

Alloy

|

Supporting

Stand

|

1

|

Iron

|

Valve

|

4

|

Plastic

|

3.2

COST

OF THE MATERIAL

Name of the parts

|

QUANTITY

|

PRICE (rupee)

|

Outer Drum

|

1

|

1000

|

Inner Drum

|

1

|

800

|

Shaft

|

3

|

2500

|

Gear

|

6

|

1200

|

Bearings

|

5

|

500

|

Chain

|

3

|

800

|

Battery

|

1

|

1200

|

Dynamometer

|

1

|

2000

|

Pedal

|

1

|

800

|

Hacksaw blade

|

1

|

300

|

Supporting

stand

|

1

|

500

|

Valve

|

4

|

500

|

Assembly Cost

|

500

|

Total Cost

|

10600

or Arround $200 |

3.4 BLOCK

DIAGRAM

In the figure the block diagram of Pedal operated washing machine has

shown .In the figure everything has been explained details means how the pedal

operated washing machine works and how it works step by step. Every single

point has been marked and indicated perfectly. First person will operate the

pedal and with help of chain the motion will transmit from the gear to the

shaft .From the shaft there two chain drive which will rotate the inner drum

and inside the drum there will be water , dirty cloths , detergent powder .

After a while the powder will dissolve and dirty cloths will be cleaned. There

will be one more hole by that the water may remove and the wet clean cloths

will be there.

Fig3.4 : Block diagram of Pedal operated

washing machine.

3.5 Working Model

in CAD

The working model of Pedal Operated washing Machine has been implemented

in mechanical software Inventor 2016 in the figure. In the figure we can see

the complete working model of the POWM where all the parts are assembled

perfectly according to the design. In this design all the support are given for

the maximum safety.

Fig 3.5 : The working model of Pedal operated machine in the CAD.

3.6 Specification of Pedal

Operated Washing Machine

The main specification of the pedal operated

washing machine is free of cost , required less amount of water and consume

zero energy except human resources .In addition the use will burn his own fat

while operating the pedal operated washing machine. The running cost is under

100 rupees. This pedal operated washing machine can wash 8 to 10 cloths at a

time with cost of 10 rupees detergent powder. It is required less than 15

minute to wash more than 8 or 10 cloths a time. Another Specification of this

pedal operated washing machine that operator can use this machine while doing

other works like watching TV , Reading Book , while gossiping with others or

listening music.

3.7 CALCULATIONS

We have assumed an overall calculations for our project. Here is the

assumption in short:

·

Length

of the shaft = 1100 mm

·

Diameter

of main shaft = 10 mm

·

Outer

drum length = 800 mm

·

Outer

drum diameter = 200 mm

·

Inner

drum length = 600 mm

·

Inner

drum diameter = 160 mm

·

First

chain drive centre to centre distance = 500 mm

·

Number of teeth of small gear = 18

·

Diameter

of small gear = 75 mm

·

Number

of teeth of larger gear = 44

·

Diameter

of larger gear = 180 mm

We are going to apply the following formulas for our project. (As our all

dimensions are assumed we could not calculated the actual calculations, as it

may vary in later)

● Angular velocity, w=

2πN/60

Where N= rpm

W= angular velocity.

● Gear ratio, G=

Our Gear Ratio = 1:5

● Torque= Force ×Radius

● Power = 2πNT/60

● RPM generated by pedalling = 50 RPM

● RPM of the main shaft = 250 RPM

v As average cyclist can can generate 183 watts

power while running at a speed of 30.4 km/hr or 8.44 m/s,

Thus power transmitted from driving sprocket to driven sprocket,

Power = Force * Velocity

so, Force = (Power/Velocity)

= (183/8.44)

= 21.68 N

v An

average cyclist can generate upto 80 rpm, as we can consider 60 rpm

and our velocity ratio is 1:3

Speed of main Shaft

Velocity ratio

N1/N2

N2= 60*3 = 180

rpm

v Torque = Force * Radius

As

our inner drum diameter d = 160 mm

& radius r

= 80 mm

Torque

= (21.68*0.08) Nm

= 1.733 Nm

v Power required to rotate inner drum at 180 rpm

P =

= 32.60 watt.

we increase the diameter of inner drum to 500

mm

&Radius = 250

mm

=

0.25m

Torque

=( Force * Radius)Nm

=(21.68*.25) Nm

=5.42 Nm

Power require to rotate inner drum at 180 rpm

P =

= 102.16 watt

We decrease the diameter of inner drum to 100

mm

Radius = 50 mm

= 0.05 m

Torque =

(21.68*0.05)N.m

=

1.084 N.m

Power

required to rotate at 180 rpm

P =

= 20 watt

We can

say that the required power is proportional to the inner drum size.If we

increased the drum diameter the required power is more .

3.8 Battery

capacity:

As we are going to add a battery for dual

mode operation, we calculated the battery capacity also.

We will attach two motors in our project.

For two motor = 12 volt, 3 amp.

3.9 ADVANTAGES

1. Saves water, time and energy.

2.

Manufacturing cost is low.

3.

Adequate maintenance cost.

4. Easy

to operate.

5.

Physical Exercise.

3.10 DISADVANTAGES

• It is not suitable for all ages.

• The capacity is less in washing cloths.

4. Conclusion

The machine must be inexpensive and easy

to build if it will be adopted into the community. We recognized this need and

designed the machine from the start with low cost in mind. The machine will

only contain parts that are readily available in rural areas. This eliminates

the need to order or import components just for the washing machine. The

machine also uses bicycle parts for all the precision parts. These parts are

very inexpensive because rural areas have a surplus of unused bicycle parts.

The working of pedal-powered washing machine is quite different from the

community’s current method of washing clothes; the community may be reluctant

to try the new machine. To understand and encourage the adoption of the washing

machine, we will apply multiple trials with local women so we can adjust the

design to meet their needs, demands. We will run the trial periods with groups

like the women’s cooperative who are already familiar with pedal powered

machines; they have already proved they are willing to try new technologies. If

women in the cooperative accept and use the machines, then they will serve as

spokes-people for the new machine in their local community.

Their support

will greatly increase the credibility of the machine so that local people will

desire to try it. We achieved what we desired i.e. building a manually driven

pedal powered low cost washing machine using locally available materials and

performing necessary function of washing and rinsing with ease. As Our washing

machine doesn’t consume electricity, This type can be used by the urban people

also while workout and exercises. It can serve dual purposes. While cycling,

the clothes can be washed utilizing the pedalling of the human being. If the

production of this washing machine is done at commercial scale then the total

production cost of the machine can be reduced to 40% of estimated cost.

5. REFERANCE

4. http://www.youtube.com

5.

http://www.hygieneforhealth.com

6.

http://www.oldandinteresting.com

7.

http://www.dictionary.com

8.

http://www.ohea.on.ca

9. Design

& Fabrication of Manually Driven Pedal Powered Washing Machine, Ajay

10. Fabrication

and Analysis of Bicycle Washing Machine,N.Balajiganesh *, K.Ram Prasad

Reddy,Assistant Professor, Mechanical Department, Aditya college of Engineering,Madanapalle,Andhra

Pradesh, India

11. Pedal

Powered Washing Machine (PPWM) ,Adarsh Ranjan, Kushagra Sharan, Sudeep Mazumdar

.

12. International

Journal of Computer Trends and Technology (IJCTT) – volume 3 Issue 6 Number 1 –

Nov 2012 ,ISSN: 2231-2803, http://www.ijcttjournal.org , Page 20 ,

13. DESIGN

AND FABRICATION OF PEDAL POWER WASHING MACHINE.

14. FOOT-POWERED

WASHING MACHINE PUTS A SPIN ON MANUAL CLOTHES WASHING.

15. http://www.treehugger.com/gadgets/foot-powered-washing-machine-lets-you-clean-your-clothes-grid.html.

For more Inquiry

Email dibakarkarmokar@gmail.com

For more Inquiry

Email dibakarkarmokar@gmail.com

Amazing information shared, Thanks.

ReplyDeletestone washing

Pedal Operated Washing Machine Of Cost >>>>> Download Now

Delete>>>>> Download Full

Pedal Operated Washing Machine Of Cost >>>>> Download LINK

>>>>> Download Now

Pedal Operated Washing Machine Of Cost >>>>> Download Full

>>>>> Download LINK cO

What a blog post! I looked many blog about this topic. But I found this blog perfect about. Thanks for this informative post.

ReplyDeletePlumber St helens

Certain automatic filling equipment is easily upgradeable to allow your packaging equipment to grow with your company. For start-up businesses, this can mean savings and increased cash flow when production demands begin to rise.

ReplyDelete.

Washing machine service in dubai

ReplyDeletehttps://www.hometech.ae/service/washing-machine-service/

UAEs Authorized Major brand Washing Machine Service in Dubai, On-Demand experienced professionals for washing machine service in Dubai.

1632715317478-9

I've bookmarked it in my Google bookmarks.

ReplyDeleteHello there, simply became alert to your blog through Google, and found that it is really informative. I am going to be careful for Brussels.

I'll be grateful when you precede this in future.

A lot of folks shall be benefited out of your writing.

Cheers!

Bosch Washing Machine Repairs

Miele Dishwasher Repairs

Pedal Operated Washing Machine Of Cost >>>>> Download Now

ReplyDelete>>>>> Download Full

Pedal Operated Washing Machine Of Cost >>>>> Download LINK

>>>>> Download Now

Pedal Operated Washing Machine Of Cost >>>>> Download Full

>>>>> Download LINK So

This information has many things to read and I am glad to read more impressive information about it. Thank you so much for the share, Also check Professional Viking Repair Service

ReplyDeleteIf your Washing machine, Dishwasher or Dryer has stopped working, you need professional help. This is where we step in to repair your appliances.

ReplyDeleteWith all the experience and expertise, we are a service to rely on. For an extended life of an appliance, its maintenance is important. However, if your appliance is causing trouble, we are here to provide any Miele Dishwasher Repairs.